| Guangdong KST Optical Co., Ltd. Product Parameters | standard encdoing: | KST-PDATA-05 | |||||

| Release date: | 9/9/2019 | ||||||

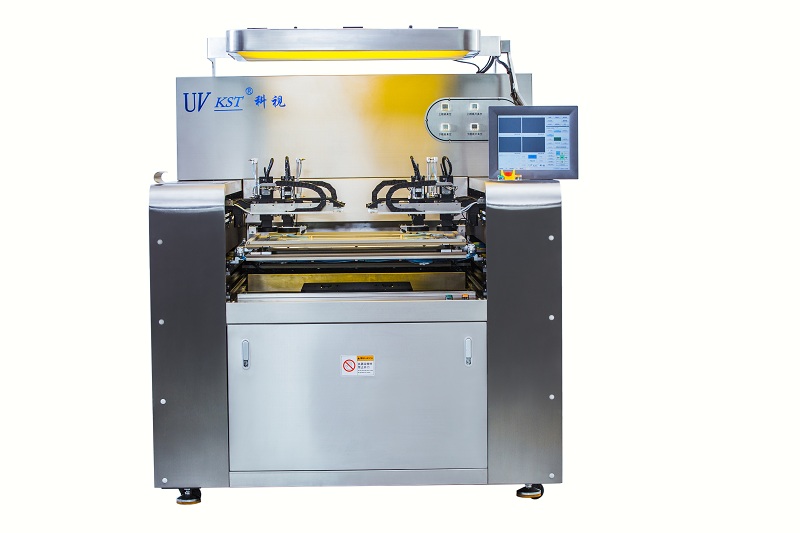

| Semi-automatic LED solder mask exposure machine(Single side expose) | Implementation date: | 2019/9/11 | |||||

| version number: | V1.0 | ||||||

| prepared by: | Review: | Approval: | |||||

| Technical parameters of semi-automatic LED solder mask exposure machine | |||||||

| Serial number | project | Technical Parameters | Note | ||||

| □ KST-SA6457-FH | □ KST-SA7262-FH | ||||||

| 1 | type of light source | UV-LED | Parallel cold light source | ||||

| 2 | Applicable ink | Green oil, black oil, blue oil, etc. | Mainstream brand | ||||

| 3 | Exposure method | Single-sided exposure | / | ||||

| 4 | Green Oil Bridge | Green oil bridge 3.0mil / solder-proof window 1.5mil | / | ||||

| 5 | Energy uniformity | ≥85% | Measured with KST LED dedicated energy meter | ||||

| 6 | Registration accuracy | ± 12.5um / ± 0.5mil | / | ||||

| 7 | Exposure control | 0-100% light intensity can be adjusted | / | ||||

| 8 | Alignment system | 4 CCD, CCD can move freely | / | ||||

| 9 | Exposure time | 9-12 level energy exposure time <10S | 21-level energy meter, the specific time depends on the ink used | ||||

| 10 | Production size | 12 "× 12" (min) | 12 "× 12" (min) | ||||

| 21.5 "× 24.5" (max) | 24.5 "× 28.5" (max) | ||||||

| 11 | Capacity | 3.5-4 faces / minute | / | ||||

| 12 | Board thickness range | 0.1mm-3.5mm (including copper thickness) | / | ||||

| 13 | Production board capacity | < 2.0kg | / | ||||

| 14 | Negative film fixing method | Vacuum adsorption | / | ||||

| 15 | Exposure film size | 24 "× 28" | 26 "× 30" | / | |||

| 16 | Average power | <5.0KW | <5.5KW | / | |||

| 17 | UV-LED lamp life | Warranty for three years | / | ||||

| 18 | Control system and interface | Chinese touch PC control display | / | ||||

| 19 | Window range | 6.9mm × 5.1mm | / | ||||

| 20 | Alignment method | Double frame operation, automatic movement | / | ||||

| twenty one | Optical glass | High-strength optical glass | / | ||||

| twenty two | Table temperature | 22 ℃ ± 3 ℃ | Need to ensure that the workshop ambient temperature is within the required range | ||||

| twenty three | Protective function | Fault alarm | / | ||||

| twenty four | Vacuum requirements | Frame: 10cmhg-30cmhg | / | ||||

| Negative film:> 60cmhg | |||||||

| 25 | Environmental requirements for clean rooms | Temperature: 22 ℃ ± 1 ℃ | |||||

| Humidity: 55% ± 5% | / | ||||||

| 26 | Pressure source requirements | 5.5kg / cm², flow 500L / min | / | ||||

| 27 | Ice water demand | 7-12 ℃, flow rate 5L / min, pressure 2-3kg / cm² | |||||

| 28 | Power requirements | Three-phase five-wire 380VAC / 50Hz / 30KVA | Three-phase five-wire 380VAC / 50Hz / 35KVA | / | |||

| 29 | Equipment size | 2780 (L) × 1650 (W) × 1980 (H) | 3015 (L) × 1730 (W) × 1980 (H) | Does not include the space occupied by the sticky wheel tray; does not include accessories such as ice water machines, vacuum pump boxes | |||

| 30 | equipment weight | 1600Kg | 1800Kg | ||||

| 31 | Safety | Meet national security standards | / | ||||

| 32 | abnormal detection | The machine has an abnormality during production and has an alarm function | / | ||||